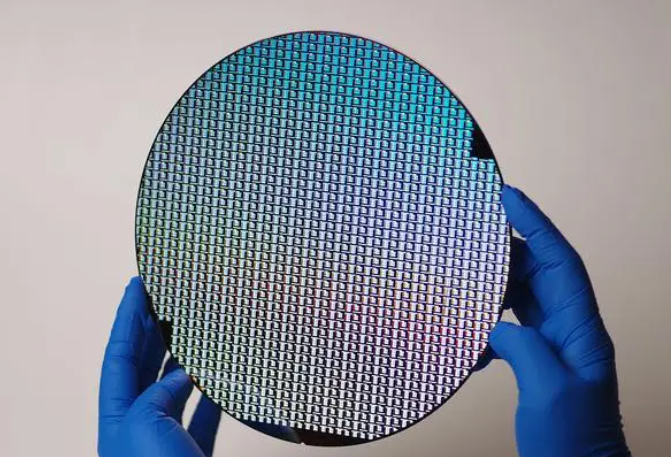

Why are silicon wafers still the first choice for more than 80% of chips?

Now the development of this technology is known as fast, and the role of the semiconductor industry in it is a bar. Smartphones, computers and home appliances, almost all modern high-tech gadgets, rely on chips. In this pile of materials, silicon with its unique process and super processing capacity, more than 80% of the chip manufacturing must choose it as a raw material!

Let's talk about the physical and technical advantages of silicon. Silicon as an element, its semiconductor properties are quite excellent, its bandwidth (band gap) is about 1.1 electron volts, at room temperature conductivity that is not to say. This makes silicon an excellent material for making transistors and other electronic components, especially where high electrical conductivity and low power consumption are required.

Silicon is not only conductive, thermal conductivity is also very good, radiation resistance is also very strong, even in high temperature, high radiation environment, electrical performance is still very stable. In addition, silicon has excellent chemical stability, is resistant to oxidation, and can maintain good performance under various environmental conditions.

Talk more about cost-effectiveness. Silicon wafers can occupy a dominant position in the market for a long time, and economic benefits are one of the important reasons. The extraction and purification cost of silicon is not high, and silicon resources in the world are quite rich. This resource is ubiquitous, which not only ensures the stability of the supply chain, but also keeps the overall production cost of silicon-based semiconductors relatively low.

Compared with other materials that may replace it (such as germanium, gallium nitride, etc.), the manufacturing process of silicon wafers is quite mature, and the development and application of related equipment and technologies are slowly standardized. This allows chipmakers to produce at lower cost and risk, and market prices will fall further.

And compatibility with existing technologies. Silicon is something we have used for a long time, and the accumulation of technology is also quite rich. From material selection to design layout, and then to wafer processing, in all aspects of chip manufacturing, the application of silicon wafers has penetrated into the entire industrial chain. Existing semiconductor manufacturing technologies, equipment and processes are highly optimized for silicon with high production efficiency and low defect rates.

The widespread use of silicon-based materials has also led to the development of software tools that effectively support circuit design and simulation. If the new material is used to manufacture HY51V16400AJ-60 chip, it will need to re-develop many processes and tools, which is time-consuming, high cost, and difficult to transfer technology.

Then there is the high level of integration and performance. Silicon chips can support the design of multi-layer integrated circuits, with high integration and stronger chip functions. This highly integrated nature makes silicon wafers particularly suitable for the design needs of mobile devices, computers, and other electronic devices. As the technology continues to advance, the chip can now integrate billions of transistors on a small piece of silicon, with great improvements in computing power and energy efficiency.

Moreover, with the continuous reduction of process nodes, the physical properties of silicon materials are still very good, and the application in nanoscale processes is particularly important. While quantum effects can be encountered at very small sizes, silicon-based technologies can address these issues with advanced process and material improvements.

This kind of silicon wafer can occupy the market, not only the material itself is good, but also benefit from a mature industrial ecology. Now the world has established a complete silicon semiconductor industry chain, from raw material suppliers to equipment manufacturers, and then to design and test companies, each link has a tacit cooperation, forming a highly collaborative network. Such cooperation not only guarantees product quality and production efficiency, but also provides a good environment for technological innovation.

At the same time, the widespread use of silicon wafers has also prompted the introduction of many industry standards, such as the size and purity requirements of various silicon wafers, as well as production process specifications. These standardized operations further reduce the technical threshold between different manufacturers, and the product launch and promotion speed is faster.

Although silicon wafers now dominate chip manufacturing, they are not without challenges. In recent years, new materials such as gallium nitride and silicon nitride have emerged slowly, and their prospects in high-frequency and high-power applications are quite good. However, there is a growing trend to combine silicon with these new materials, resulting in so-called "heterostructure" technologies.

Combining the new material with silicon-based materials allows for higher performance in specific application scenarios. For example, taking advantage of the high electron mobility of gallium nitride and the low cost of silicon, more efficient power amplifiers and RF components can be made, and the new material has a wider range of applications.

Finally, let us look to the future. Silicon wafers will play an important role in the future of the semiconductor industry. Although there are more and more new materials and their excellent performance, the uncertainty of the market, the complexity of technology transfer, and the high cost of manufacturing these factors make the market position of silicon wafers is still very stable. As the technology evolves, the combination of silicon and other new materials will take the semiconductor industry to the next level and help enable a variety of emerging applications. Whether it is deep learning, big data, or the Internet of Things (IoT), the continuous development of silicon chips will continue to play an irreplaceable role in future technological change.

Die Produkte, an denen Sie interessiert sein könnten

|

AOZ1043PI-01 | IC REG BUCK SYNC 8SOIC | 3294 More on Order |

|

AOZ1017AIL#A | IC REG BUCK ADJUSTABLE 3A 8SOIC | 2160 More on Order |

|

AOZ1024DIL_4 | IC REG BUCK ADJUSTABLE 4A 8DFN | 7236 More on Order |

|

AOZ1012DI | IC REG BUCK ADJUSTABLE 3A 8DFN | 3960 More on Order |

|

AOZ1320DI-04L#A | IC POWER DIST LOAD SW 8DFN | 6642 More on Order |

|

AOZ1312EI-1 | IC PWR DIST SW USB 1CH 8MSOP | 3490 More on Order |

|

AOZ9216DI | BATTERY PROT | 3870 More on Order |

|

AO3415B | MOSFET 2P-CH 30V 6A 8-SOIC | 5004 More on Order |

|

AON6928 | MOSFET 2N-CH 30V 17A/30A 8DFN | 6408 More on Order |

|

AO4447AL_201 | MOSFET P-CH 30V 8SOIC | 6840 More on Order |

|

AOD418G | MOSFET N-CH 30V DPAK | 3474 More on Order |

|

AOD210 | MOSFET N-CH 30V 70A TO252 | 6354 More on Order |

|

AOB1606L | MOSFET N-CH 60V 12A TO263 | 8316 More on Order |

|

AOWF412 | MOSFET N-CH 100V 7.8A TO262F | 3114 More on Order |

|

AOT7S60L | MOSFET N-CH 600V TO220 | 3366 More on Order |

|

AOD464 | MOSFET N-CH 105V 40A TO252 | 7524 More on Order |

|

AOD516 | MOSFET N-CH 30V 18A TO252 | 3816 More on Order |

|

AON7752 | MOSFET N-CH 30V 15A 8DFN | 4860 More on Order |

|

AOD21357 | MOSFET P-CH | 3312 More on Order |

|

AOK20N60L | MOSFET N-CH 600V 20A TO247 | 7992 More on Order |

|

AO4402 | MOSFET N-CH 20V 20A 8SOIC | 44202 More on Order |

|

AO3407A | MOSFET P-CH 30V 4.3A SOT23 | 338118 More on Order |

|

AOZ8304ADI-02 | TVS DIODE 3.3V 10V | 6192 More on Order |

|

AOZ8131DI-05L | TVS DIODE 5V 22V 2DFN | 356736 More on Order |