Unlock performance potential: Three major connectivity technologies for flip chips

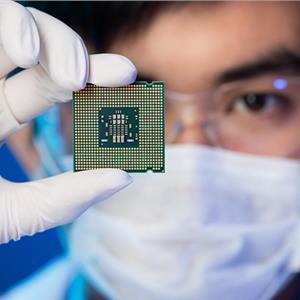

In the pursuit of higher performance and smaller size of electronic devices, Flip Chip technology has become a leader in integrated circuit (IC) package design. Innovative packaging methods bring many benefits to the semiconductor industry, the most prominent of which is its special connection technology. Here are three aspects of how flip-chip connection technology can make electronic products continue to progress.

Let's start with microwelding technology. Microwelding technology is one of the keys to flip chip connection, which allows the chip to connect with the substrate directly. That is, the welding ball (usually a tin ball) is placed on the welding pad of the flip chip, and then the chip is turned over, pressed on the substrate, and then heated, the welding ball will melt, forming a stable connection.

Do not underestimate this micro-welding technology, it can achieve a higher connection density. The balls are more evenly distributed than traditional wire connections, and the reliability of electrical connections follows. Moreover, microwelding can also reduce the signal delay caused by too long the lead, and the overall performance is improved. This is particularly important for high-frequency applications such as radio frequency (RF) and high-speed digital circuits, where signal integrity is critical.

Not only that, the adaptability of this micro-welding technology is also particularly strong, and different solders and process parameters can be selected according to different needs, and the connection performance is further optimized. This creates good conditions for the development of high-performance, low-power devices, but also to meet the growing demand of the market.

Let's talk about grid array technology. The Ball Grid Array (BGA) is another highly innovative form of technology in flip chip connectivity. Compared with the traditional flat package, the BGA method is to spread the welding balls evenly across the bottom of the chip, spreading the connection points over a larger area. This benefit can be much more, both to improve the thermal dispersion performance, but also to a certain extent to reduce the physical stress, so that the risk of failure caused by welding defects is low.

BGA is designed to efficiently transfer heat from the chip to the substrate, eliminating the problem of local overheating. In high power devices and high frequency applications, BGA technology has excellent thermal management capabilities, which can effectively support higher power and faster operation. Because of this, flip chips are widely used in many fields such as consumer electronics, automotive electronics and communication equipment.

As technology continued to advance, variants of the BGA came out one by one, like a Solder Ball Array (SBA) and Chip Scale Package (CSP). These new designs can not only further compress space and improve integration, but also provide more flexible connections in design, bringing more possibilities to the research and development team.

And finally, advanced material technology. The progress of this connection technology is inseparable from the development of materials science. The welding materials, packaging materials and substrate materials used in flip chip technology are constantly innovative. For example, the low melting point alloy solder used in recent years (like microalloyed tin solder) has better fluidity and weldability, which can bring down the welding temperature and reduce thermal damage to the chip and substrate. The new polymer packaging material not only has good mechanical properties and electrical insulation properties, but also provides effective packaging protection.

This advanced material technology also includes high thermal conductivity substrates and composite materials, which can not only increase the thermal conductivity, but also reduce the resistance, so that the overall performance of the chip is increased. Flip chips with high thermal conductivity substrates dissipate heat faster, which can make the chip more stable when working, especially for those circuits operating in high temperature environments, which is particularly important.

In addition, emerging technologies such as conductive adhesives and ultrasonic welding are also constantly promoting the connection performance of flip chips. The application of these new material technologies has greatly expanded the application range of flip chips, making its performance under extreme conditions of high frequency, high power and high temperature more and more wonderful.

In the future, the three major connection technologies of flip chips - micro-welding technology, grid array technology and advanced material technology - not only promote the innovation of semiconductor packaging technology, but also stimulate the performance potential of various electronic products. These technologies are integrated and developed together, laying a solid foundation for the future of the electronics industry. Like behind every chip, there are endless possibilities. With the continuous progress of science and technology, the application field of flip chips will be more and more extensive, and its technological innovation will continue to push the entire industry forward.

Die Produkte, an denen Sie interessiert sein könnten

|

3424 | RUGGED METAL ON/OFF SWITCH | 8892 More on Order |

|

481 | RUGGED METAL PUSHBUTTON | 8982 More on Order |

|

1192 | SWITCH PUSHBUTTON SPST-NO WHT | 6984 More on Order |

|

166 | ROUND FORCE-SENSITIVE RESISTOR | 4320 More on Order |

|

4019 | US-100 ULTRASONIC DISTANCE SENSO | 8244 More on Order |

|

3397 | OPTOMAX DIGITAL LIQUID LEVEL SEN | 6324 More on Order |

|

381 | WATERPROOF DS18B20 DIGITAL TEMPE | 14292 More on Order |

|

3686 | SENSOR AIR QUALITY | 7686 More on Order |

|

3239 | 802.3AF POE OUTPUT DATA & POWER | 4482 More on Order |

|

407 | ELECTROLUMINESCENT WIRE GRN 2.5M | 6552 More on Order |

|

2506 | NEOPIXEL DIGITAL RGB LED STRIP - | 2286 More on Order |

|

1547 | ADDRESS LED STRIP SPI RGB 2080MM | 6372 More on Order |

|

1938 | ADDRESS LED DISCRETE SER RGB 5MM | 512 More on Order |

|

2157 | ADDRESS LED 14 SEG I2C WHITE | 6840 More on Order |

|

2958 | ADDRESS LED STRIP SERIAL RGB 1M | 4248 More on Order |

|

3587 | ADDRESS LED DISCR SER RGB 100PK | 8820 More on Order |

|

2659 | ADDRESS LED DISCR SER RGB 1=10 | 20208 More on Order |

|

3867 | FLEXIBLE SILICONE NEON-LIKE LED | 6678 More on Order |

|

3861 | FLEXIBLE SILICONE NEON-LIKE LED | 4896 More on Order |

|

333 | TOUCH SCREEN RESISTIVE 3.2"" | 7164 More on Order |

|

3787 | 1.54"" 240X240 WIDE ANGLE TFT LCD | 8280 More on Order |

|

2050 | 3.5"" TFT 320X480 TOUCHSCREEN | 7296 More on Order |

|

619 | SMT RGB 5050 LED - 10 PACK | 5796 More on Order |

|

2948 | LED CHARLIEPLEXED MATRIX - 9X16 | 7488 More on Order |