MEMS sensors: the core perception technology of the digital age

In this era of increasingly fierce digital transformation and the development of Internet of Things (IoT) technology, MEMS sensors are an important part of modern perception technology. It is slowly changing the way we perceive and interact with the world around us.

What is a MEMS sensor? It is a multi-functional sensor that combines micromachinery and electronic technology, which is small, consumes less power, and has low manufacturing cost, bringing super sensing capabilities to various smart devices.

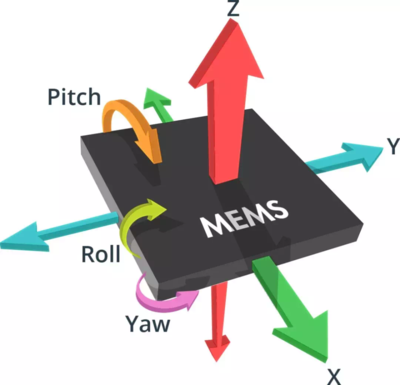

The structure and working principle of MEMS sensor. It mainly includes micromechanical components, electronic circuits and packaging materials. Micromechanical components are generally made of silicon materials, through the micron-scale processing technology, to create the core components of various sensors, such as accelerometers, gyroscopes, pressure sensors and so on. The electronic circuit is responsible for collecting and processing the signals of the micromechanical components, and then turning them into digital signals for further analysis and processing.

For example, MEMS accelerometers, which work by using micromechanical structures to sense changes in the acceleration of objects. If the object accelerates or decelerates, the mass in the micromechanical element will move, and by detecting the movement of this mass block, the acceleration of the object can be accurately calculated. Because of this principle, accelerometers can detect direction and motion not only on consumer electronics such as smartphones and tablets, but also in many industries such as automobiles, aviation, and medical care.

Types of MEMS sensors:

1. Accelerometer: It can measure the change of the acceleration of the object, which is used in consumer electronics, automobiles, and industrial equipment.

2. Gyroscope: can measure the angular speed of the object, often used with an accelerometer to know the three-dimensional attitude of the object.

3. Pressure sensor: It can measure the pressure of gas or liquid, which is used in meteorological monitoring, aerospace, medical treatment, industrial automation and other fields.

4. Temperature sensor: It can measure the temperature of the environment or objects, and can be used in many occasions such as HVAC, industrial process control, and automobiles.

5. Humidity sensor: It can detect air humidity and is widely used in meteorological monitoring, agriculture and environmental monitoring.

6. Magnetic sensor: It can measure the strength and direction of the magnetic field, which is useful in navigation, automotive electronics, and smart wearable devices.

MEMS sensors are widely used in many industries because of their small size, integration, and low power consumption, especially in the fields of consumer electronics, automotive, medical, environmental monitoring, and industrial automation.

In the field of consumer electronics, MEMS sensors bring dynamic direction detection, attitude control and motion recognition to smartphones and tablets, making the user experience more direct and user-friendly. For example, through the combination of MEMS accelerometers and gyroscopes, users can easily rotate the screen and have more control when playing games.

In the automotive industry, MEMS sensors play a big role in safety and stability. Working with the accelerometer and gyroscope, the car can monitor its driving status in real time, and the driver assistance system can react quickly in unexpected situations, making the car safer. In addition, pressure sensors are also important in tire monitoring and engine management.

In the medical industry also because of the development of MEMS technology has gained a lot of benefits, MEMS sensors are used in a variety of medical equipment, such as thermometers, heart rate monitors, blood glucose meters and so on. These sensors can collect patients' physiological data in real time, making medical examinations and monitoring more accurate and efficient.

In the field of environmental monitoring, MEMS sensors can collect environmental data quickly and accurately. For example, humidity sensors and temperature sensors together, can help do weather forecasting and environmental protection, monitoring air quality, soil moisture, etc., to provide reliable data support for management and decision-making.

In industrial automation, MEMS sensors can make devices smarter, supporting real-time monitoring and predictive maintenance. By integrating various types of AQ06EM1R2CAJ1A sensors, factories can fully monitor the production process, improve production efficiency, reduce energy consumption and operating costs.

So how will MEMS sensors develop in the future? As technology continues to advance, there are several big trends in MEMS sensors in technology and applications. First, performance improvement is an important direction. Future MEMS sensors will be more sensitive, less noisy, and have a larger dynamic range, so that they can meet more complex measurement needs.

Secondly, integration is also an important trend in the development of MEMS sensors. More and more functions will be integrated into a MEMS chip, such as an accelerometer, gyroscope, and pressure sensor, which will provide more comprehensive perception. This integration will allow sensors to be used more widely in smart devices, and also make system design simpler and less costly.

At the same time, the demand for low power consumption and high precision will also promote the development of MEMS technology. Many application scenarios need to run for a long time without changing the battery, which will promote a breakthrough in power consumption optimization of MEMS sensors, so that it has a greater use in Internet of Things devices and wearable technology.

Finally, advances in materials science will also provide a broader application base for MEMS sensors. The application of new materials allows MEMS sensors to maintain high performance even in extreme environments, which can expand its application scenarios.

As an important sensing tool in the digital age, MEMS sensor's technological progress and application expansion will have a profound impact on various industries. In the digital world of the future, MEMS sensors will continue to be a core force for intelligent, automated and data-driven decision-making.

Die Produkte, an denen Sie interessiert sein könnten

|

62054-P2S02 | XFRMR TOROIDAL 15VA CHAS MOUNT | 3526 More on Order |

|

62043-P2S02 | XFRMR TOROIDAL 10VA CHAS MOUNT | 5472 More on Order |

|

62035-P2S02 | XFRMR TOROIDAL 7VA CHAS MOUNT | 6642 More on Order |

|

62034-P2S02 | XFRMR TOROIDAL 7VA CHAS MOUNT | 7938 More on Order |

|

62025-P2S02 | XFRMR TOROIDAL 5VA CHAS MOUNT | 3924 More on Order |

|

62012-P2S02 | XFRMR TOROIDAL 3.2VA CHAS MOUNT | 3204 More on Order |

|

62005-P2S02 | XFRMR TOROIDAL 1.6VA CHAS MOUNT | 7668 More on Order |

|

62073-P2S02 | XFRMR TOROIDAL 35VA CHAS MOUNT | 5292 More on Order |

|

70074K | XFRMR TOROIDAL 35VA THRU HOLE | 6840 More on Order |

|

70072K | XFRMR TOROIDAL 35VA THRU HOLE | 5634 More on Order |

|

70041K | XFRMR TOROIDAL 10VA THRU HOLE | 2826 More on Order |

|

70014K | XFRMR TOROIDAL 3.2VA THRU HOLE | 5562 More on Order |

|

70002K | XFRMR TOROIDAL 1.6VA THRU HOLE | 5040 More on Order |

|

70025K | XFRMR TOROIDAL 5VA THRU HOLE | 4068 More on Order |

|

62082-P2S02 | XFRMR TOROIDAL 50VA CHAS MOUNT | 4986 More on Order |

|

62033-P2S02 | XFRMR TOROIDAL 7VA CHAS MOUNT | 6480 More on Order |

|

62024-P2S02 | XFRMR TOROIDAL 5VA CHAS MOUNT | 4824 More on Order |

|

62084-P2S02 | XFRMR TOROIDAL 50VA CHAS MOUNT | 7284 More on Order |

|

70064K | XFRMR TOROIDAL 25VA THRU HOLE | 13758 More on Order |

|

70034K | XFRMR TOROIDAL 7VA THRU HOLE | 8088 More on Order |

|

70005K | XFRMR TOROIDAL 1.6VA THRU HOLE | 7218 More on Order |

|

AC1200 | CURR SENSE XFMR 200A T/H | 2142 More on Order |

|

AC1050 | CURR SENSE XFMR 50A T/H | 7362 More on Order |

|

AC1015 | CURR SENSE XFMR 15A T/H | 5166 More on Order |