Leapfrog tactile cognition in robots: application of hydrogel technology

In the current era of rapid technological development, the research of robot tactile cognition has become a highlight in the intersection of artificial intelligence, robotics science and materials science. With the deepening of human-computer interaction, how to improve the robot's tactile perception of objects has become an urgent issue to be solved. Hydrogel technology, with its good biocompatibility, adjustability and excellent mechanical properties, is gradually exploring a new way to provide strong support for the research of robot tactile cognition.

The basis of hydrogel technology

Hydrogels are polymers with a three-dimensional network structure that contain at least 90% water, and their unique physical and chemical properties allow them to be used in a wide range of applications. From soft tissue repair and drug release in medicine, to environmental monitoring and food packaging, hydrogels show unique value in many fields due to their excellent water absorption and biocompatibility. In the field of robotics, especially in the development of tactile sensors, the application of hydrogels is achieving remarkable results.

The need for tactile sensors

The tactile sensor is a key component used to obtain the contact information between the robot and the surrounding environment. Compared with sight and hearing, tactile perception provides robots with more direct and richer information. This information can help robots perform precise operations in complex environments, such as object grasping, recognition and manipulation. The improvement of tactile perception needs to rely on advanced sensor technology, and the introduction of hydrogel materials provides an important new option for the development of this technology.

Application of hydrogels in tactile sensors

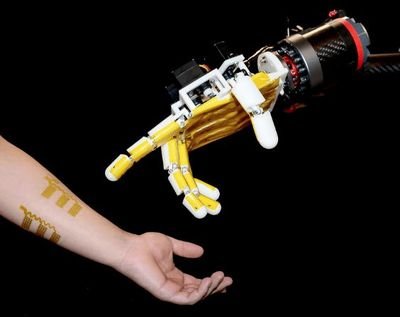

Using the soft and elastic properties of hydrogels, the scientists developed a variety of new tactile sensors, demonstrating its potential to improve the tactile cognition of the AM27C256-12JL robot. These sensors often combine electrical conductivity changes, optical characteristics and other output methods, so that they can accurately feedback multidimensional tactile information such as pressure, temperature, shape changes.

1. High sensitivity tactile sensor

A typical hydrogel tactile sensor consists of a polymer network and conductive material. By optimizing the structure and composition of the hydrogel, the researchers can achieve extremely high sensitivity, capturing small pressure changes. This sensor can not only recognize different contact forces, but also quickly evaluate the characteristics of the touched object, making the robot more intelligent when performing operations, and can adapt to different tactile feedback in a diverse environment.

2. Multi-functional tactile system

In some cutting-edge research, scientists are trying to combine hydrogel materials with other sensing technologies to create multifunctional tactile systems. This system not only has the traditional tactile perception ability, but also can enhance the robot's environmental cognition ability by integrating other sensing functions such as temperature and humidity. For example, one study combined hydrogel tactile sensors and temperature sensors to realize the robot's comprehensive judgment of changes in the external environment. The robot can quickly adjust its action strategy when it comes into contact with a heat source, ensuring the safety and flexibility of the operation.

3. Bionic tactile sensor

The flexibility and tenability of hydrogels make them ideal materials for tactile sensing in bionic robots. Increasingly, scientists are taking inspiration from tactile systems in nature to develop robotic systems that mimic biological touch. For example, the antenna or skin structures of some insects and mammals enable rapid feedback to the environment through efficient cell arrangement and information transmission mechanisms. With the help of hydrogel technology, developers can design similar tactile components, so that robots can not only "feel", but also "think" how to respond to different environmental factors.

Manufacturing processes and challenges of hydrogels

Although hydrogels show great potential in the field of tactile sensors, their production process and material selection remain a serious challenge. Achieving mass production of hydrogel materials while maintaining high performance requires complex chemical reaction processes and strict control of process conditions. In addition, the aging, durability and performance of hydrogels in extreme environments are also the focus of current research. How to optimize the stability of hydrogels to adapt to diverse application scenarios has become a difficult problem for developers to solve.

Future expectations

With the deepening of research, the application prospect of hydrogels in robot tactile cognition is exciting. Future scientific and technological developments may integrate more material science achievements, opening new doors for the application of hydrogel technology. Combined with emerging technologies such as machine learning and artificial intelligence, tactile systems built with hydrogels could form the next technological flashpoint in robotics.

While the production process continues to make breakthroughs, customized hydrogel materials for specific robot needs will gradually become a reality, to give robots more complex and rich tactile cognitive capabilities, and truly realize the natural and efficient human-machine interaction.

With the progress in this field, the in-depth application of hydrogel technology will not only change the tactile perception ability of robots, but also promote the rapid development of the entire intelligent robot industry.

Die Produkte, an denen Sie interessiert sein könnten

|

2677 | QI WIRELESS CHARGING RECEIVER | 4104 More on Order |

|

474 | SWITCH PUSHBUTTON SPST-NO YELLOW | 8208 More on Order |

|

1193 | SWITCH PUSHBUTTON SPST-NO GRN | 9093 More on Order |

|

1137 | MAXBOTIX WEATHER-RESISTANT ULTRA | 7794 More on Order |

|

3827 | 5 ETAPE LIQUID LEVEL SENSOR + EX | 8442 More on Order |

|

3397 | OPTOMAX DIGITAL LIQUID LEVEL SEN | 6324 More on Order |

|

377 | ROTARY ENCODER MECHANICAL 24PPR | 5400 More on Order |

|

631 | STARTER PK EL STRIP 100CM RED | 3469 More on Order |

|

588 | WIRE STARTER PK EL PNK 2.5M-8.2' | 2682 More on Order |

|

2555 | DIGITAL RGB LED WEATHERPROOF STR | 5130 More on Order |

|

2436 | DOTSTAR LED STRIP - ADDRESSABLE | 5184 More on Order |

|

2959 | ADDRESS LED STRIP SERIAL RGB 4M | 4482 More on Order |

|

2432 | DOTSTAR LED STRIP - ADDRESSABLE | 8244 More on Order |

|

3869 | NEOPIXEL RGB NEON-LIKE LED FLEX | 4482 More on Order |

|

2874 | ADDRESS LED RING 1/4 SER RGBW | 6336 More on Order |

|

1487 | ADDRESS LED MATRIX SERIAL RGB | 4860 More on Order |

|

2846 | ADDRESS LED STRIP SERIAL RGBW 1M | 6948 More on Order |

|

879 | ADDRESS LED 7 SEG I2C YELLOW | 4374 More on Order |

|

1655 | ADDRESS LED DISCR SER RGB 1=10 | 58404 More on Order |

|

2353 | TFT DISPLAY - 800X480 W/O TOUCH | 6768 More on Order |

|

1673 | BREAKOUT OLED 16BIT CLR 1.27"" | 7776 More on Order |

|

2739 | DIFFUSED RECT 5MM RGB LED 1=10 | 8604 More on Order |

|

314 | LED RGB DIFFUSED 5MM ROUND T/H | 8118 More on Order |

|

1855 | SMALL 1.2 8X8 ULTRA BRIGHT SQUAR | 5094 More on Order |