How to effectively prevent the cavity surface disaster of laser chip?

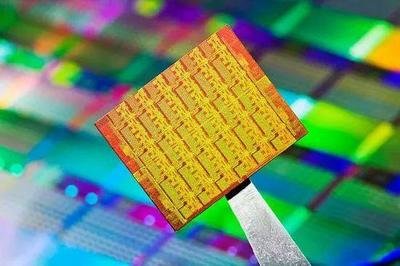

Laser chip is the core of modern optoelectronic technology, and its performance is directly related to the efficiency and stability of the laser, and how much it can be used. However, when the laser chip is working, it may encounter the cavity surface disaster, which is because the local temperature is too high, or the surface is dirty, resulting in the chip performance is not good, or even broken directly. Therefore, it is very important that we think of some effective ways to prevent this kind of surface disaster.

Let's start with materials. First, the material with high thermal conductivity must be selected, which is very important for the thermal management of the laser chip. The materials used in the cavity surface need to dissipate heat well, so that there is less trouble because the heat pile there causes the temperature to be too high. Like gallium nitride (GaN) and lithium niobate (LiNbO₃), these materials have good thermal conductivity. In addition, the coating with high reflectivity and good anti-pollution performance can make the laser lose fewer points on the cavity surface. The coating has to be designed with wavelength and environmental considerations in mind to ensure long-term stability.

Then there's the manufacturing process. The cavity surface of the 16-60-G-S-590 laser chip is particularly flat and smooth, and it is necessary to use high-precision processing equipment and technology when manufacturing, such as chemical mechanical polishing (CMP) process is very good, which can reduce surface defects and the risk of cavity surface disasters is low. In the production process, the quality control is strict, each laser chip has to be tested and inspected before leaving the factory, the optical and thermal characteristics of the cavity surface have to be checked, and do not let unqualified products run out.

Package design can't be sloppy. The laser chip will generate a lot of heat when working, so the package design needs to use thermal conductive materials to improve heat dissipation efficiency. The package structure is reasonable, which can let the heat run away quickly, and don't let the cavity surface be too hot. What's more, the package can keep out dust, moisture and other dirty things, with sealing materials or shields, so that the laser chip is more durable and reliable.

The device operating parameters have to be worked out. When the laser is working, if the driving current is too large, the cavity surface temperature will go up, and the cavity surface disaster will come. Therefore, it is necessary to set the driving current reasonably, which is the key to prevent the cavity surface disaster. Current feedback control technology can be used to keep the current in a reasonable range. It also has to detect the operating temperature of the laser chip in real time, the kind that can be automatically adjusted, so that it can avoid cavity surface problems caused by abnormal temperature. It is necessary to use high-precision temperature sensors and control systems to ensure that the operating temperature is always in a safe range.

Regular maintenance is also necessary. The cavity surface of the laser chip is easy to get dirty, so it has to be cleaned regularly. Use professional cleaning liquid and soft cloth, gently wipe the cavity surface, do not give scratches, do not leave dirty things. It is also necessary to regularly detect the performance of the laser chip, and record the changes in the working state and various parameters, so that the risk of possible cavity surface disasters can be found early, so that measures can be taken to adjust.

Research and development and technological innovation also need to be stepped up. More research is needed to study the materials of the cavity surface of the laser chip, and new high-performance materials are used in the design and production of the laser chip. For example, developing materials that are more resistant to high temperatures and pollution, so that the cavity surface is more reliable. It can also introduce artificial intelligence and Internet of Things technology, which can monitor the operating status of the laser chip in real time and analyze the data, so that possible cavity surface disasters can be effectively prevented. By analyzing the data, we can know the conditions of the cavity surface under different working conditions, to provide some basis for the optimization design.

The accumulation and sharing of experience is also important. The industry has to cooperate with each other to share the successful experience and examples of laser chips in preventing cavity surface disasters, so that the technology can communicate and progress together, so that the technical level of the entire industry can be improved faster. Also have to regularly engage in some training and education activities, so that people in this line can be more clear about the laser chip cavity surface disaster, prevention awareness can be stronger, to ensure that each link can be strictly in accordance with the method of disaster prevention.

Finally, it is necessary to establish a good market feedback mechanism to collect customers' feelings and problems with laser chips in a timely manner. By analyzing these data, we can quickly respond to various cavity surface problems encountered by customers in the process of use, and also provide support for the continuous improvement of laser chips.

If you can make the above moves, you can effectively avoid the cavity surface disaster of the laser chip, so that the laser equipment is more stable and more reliable. This can be all links in the industry together to work hard, continuous innovation, continuous progress, in order to achieve higher technical standards and product quality.

Die Produkte, an denen Sie interessiert sein könnten

|

480 | SMALL ARCADE JOYSTICK | 5526 More on Order |

|

3104 | PUSHBUTTON RED POWER SYMBOL MOM | 9930 More on Order |

|

472 | SWITCH PUSHBUTTON SPST-NO PINK | 4410 More on Order |

|

3809 | SMALL 6V 1W SOLAR PANEL - SILVER | 5166 More on Order |

|

1170 | MAGNET ROUND, SQUARE FRAME | 4644 More on Order |

|

2832 | ADDRESS LED STRIP SERIAL RGBW 5M | 3996 More on Order |

|

2533 | DOTSTAR LED STRIP - ADDRESSABLE | 2178 More on Order |

|

2038 | ADDRESS LED MATRIX I2C WHITE | 5022 More on Order |

|

1049 | ADDRESS LED MATRIX I2C RED | 7560 More on Order |

|

959 | ADDRESS LED MATRIX I2C BLUE | 4392 More on Order |

|

3635 | ADDRESS LED STRIP 1M | 6384 More on Order |

|

3811 | ADDRESS LED STRIP SERIAL RGB | 7740 More on Order |

|

1080 | ADDRESS LED MATRIX I2C WHITE | 5328 More on Order |

|

2294 | ADDRESS LED MATRIX SERIAL RGB | 6678 More on Order |

|

881 | ADDRESS LED 7 SEG I2C BLUE | 7326 More on Order |

|

2970 | ADDRESS LED STRIP SERIAL RGB 1M | 5760 More on Order |

|

2239 | ADDRESS LED STRIP SERIAL RGB 4M | 5544 More on Order |

|

3498 | PYBOARD COLOR LCD SKIN WITH RESI | 3526 More on Order |

|

4243 | 2.13"" FLEXIBLE MONOCHROME EINK / | 7866 More on Order |

|

3533 | 0.96"" 160X80 COLOR TFT DISPLAY W | 6132 More on Order |

|

1857 | SMALL 1.2 8X8 ULTRA BRIGHT SQUAR | 2790 More on Order |

|

2601 | RGB MATRIX SHIELD FOR ARDUINO | 4500 More on Order |

|

1907 | DUAL ALPHANUMERIC DISPLAY - RED | 2736 More on Order |

|

811 | YELLOW 7-SEGMENT CLOCK DISPLAY | 8442 More on Order |