How can SiC power modules drive a revolution in electric vehicle motor performance

Nowadays, the technological development of electric vehicles (EVs) has advanced by leaps and leaps, and the innovation of power electronic components is too important to improve the performance of electric vehicles, and SiC power modules are an important breakthrough in this field, which has brought great changes to the motor performance of electric vehicles.

Properties of SiC materials.

SiC is a compound semiconductor material, which has many advantages over traditional silicon materials. First, its wideband gap is amazing, it can withstand higher voltages and temperatures, which is especially good in high-power applications, and is suitable for use in electric vehicle drive systems. The bandwidth of this SiC is 3.26 electron volts (eV), which is much higher than silicon's 1.12eV, which means that SiC devices can work stably in more difficult environments.

In addition, SiC has much better thermal conductivity than silicon, which is particularly critical in high-power applications. It can manage the heat more effectively, so that the cooling requirements of the system are reduced, so that the overall efficiency is improved. In addition, the switching speed of SiC is fast, almost ten times that of silicon devices! This means that under the same conditions, the SiC module can switch faster, the energy loss is reduced, and the performance of the drive system is also up.

Application of SiC power module in electric vehicle.

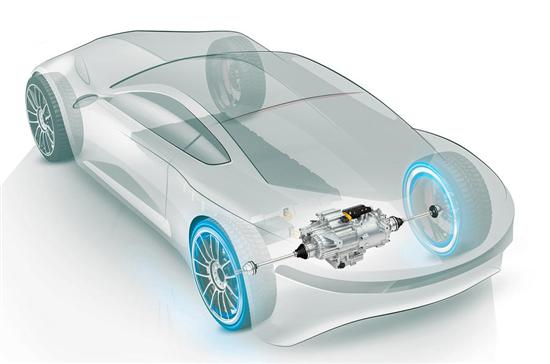

In electric vehicles, the BZX84C51NEO motor controller is connected to the motor, and the performance of this controller directly affects the power performance and endurance of the vehicle. With the motor controller of SiC power module, the stability is higher, the switching loss is lower, and the power response of the vehicle is better.

Benefits of SiC power modules

First, it can improve energy efficiency, so that the drive system of electric vehicles can more effectively convert the energy in the battery into kinetic energy. The module can be switched quickly at high frequencies, the switching loss is minimized, and the overall energy efficiency is improved. Especially when speeding up or driving at high speed, the dynamic response ability of the SiC module is strong, and the driving is smoother and the control is more stable.

Secondly, it can reduce the size and weight. Electric cars have to be designed with performance and weight in mind. This SiC power module is highly efficient, and many traditional heat dissipation methods are not needed, so that the overall volume and weight of the system are reduced. That gives designers more ideas for the architecture of electric vehicles, freeing up more space for batteries and other important components.

In addition, it can broaden the scope of application. This SiC power module can not only be used in high-power places, it works in a wide range of different types of electric vehicles, such as passenger cars, commercial vehicles and so on. This flexibility and applicability allows automakers to quickly respond to changing market demands and optimize their products.

The last point is to increase the range. By improving the energy conversion efficiency, the driving range of this electric vehicle can be improved to a certain extent. Studies have said that the improvement of energy efficiency can directly increase the battery life, which will bring more convenient experience to the owner. By reducing energy consumption, this SiC module not only makes the battery charge frequency of electric vehicles better, but also makes the car more reliable during long distances.

Economic and environmental adaptability

In terms of economy, although the production cost of this SiC material is higher than that of traditional silicon materials, the benefits are still obvious in the long run. As technology continues to improve, production has increased, and the cost of SiC power modules has slowly come down, so that more electric vehicle manufacturers can use SiC materials. In terms of environmental protection, because the use of electricity is more efficient, the SiC power module can help reduce the demand for power when the electric vehicle is driving, so the burden on the environment is small.

Thermal management and reliability

As the electric vehicle market continues to expand, this issue of thermal management is particularly important. This SiC power module not only has good thermal conductivity, but also a wide range of operating temperatures, and can also be stable in high temperature environments, so that the reliability of the system is greatly improved. Traditional silicon devices are prone to performance degradation in high temperature environments, but this SiC module works stably, and the overall service life of the car is improved, especially suitable for use in extreme weather conditions, so that the adaptability of electric vehicles is stronger.

Motor drive characteristic

The electric motor of electric vehicles has high efficiency and fast response, and the requirements for power modules are higher. The advantage of this SiC power module in this regard is not only the fast switching speed, but also the accurate control of the output power of the motor, so that the electric vehicle can have enough power at any time. In addition, the high-frequency switching characteristics of the SiC module can also make the operation performance of the motor better, whether it is low speed or high speed, it can perform particularly well to ensure that the car is no problem under various driving conditions.

With the continuous progress of SiC technology, the electric vehicle market is expanding rapidly, which is based on the SiC electric vehicle motor drive system is moving towards higher efficiency, smaller volume, more adaptable direction, to the future electric mobility provides a particularly strong support!

Die Produkte, an denen Sie interessiert sein könnten

|

CAR1212FPBC-Z01A | AC/DC CONVERTER 12V 1200W | 4986 More on Order |

|

ESTW025A0F641-HZ | DC DC CONVERTER 3.3V 83W | 4500 More on Order |

|

QW010A0A1-BH | DC DC CONVERTER 5V 50W | 2628 More on Order |

|

LW010B | DC DC CONVERTER 12V 10W | 8118 More on Order |

|

HC006A6A1-S | DC DC CONVERTER 5V 33W | 2772 More on Order |

|

QBDE067A0B641-PHZ | DC DC CONVERTER 12V 804W | 5382 More on Order |

|

IND065BHV | DC DC CONVERTER 32-54V 65W | 3816 More on Order |

|

NSR006A0X4Z | DC DC CONVERTER 0.6-6V 36W | 12468 More on Order |

|

BZX84C5V1LWP | DIODE ZENER 5.1V 250MW SOT23 | 3096 More on Order |

|

BZX84C24 TR | DIODE ZENER 24V 350MW SOT23 | 2754 More on Order |

|

BZX84C75LT3 | DIODE ZENER 75V 225MW SOT23-3 | 5598 More on Order |

|

BZX84C10LT3G | DIODE ZENER 10V 225MW SOT23-3 | 2430 More on Order |

|

BZX84B62-G3-08 | DIODE ZENER 62V 300MW SOT23-3 | 5850 More on Order |

|

BZX84B47-G3-18 | DIODE ZENER 47V 300MW SOT23-3 | 8928 More on Order |

|

BZX84W-B43X | BZX84W-B43/SOT323/SC-70 | 7002 More on Order |

|

BZX84C7V5-G3-18 | DIODE ZENER 7.5V 300MW SOT23-3 | 4878 More on Order |

|

BZX84B4V7-HE3-08 | DIODE ZENER 4.7V 300MW SOT23-3 | 884 More on Order |

|

BZX84B18-HE3-18 | DIODE ZENER 18V 300MW SOT23-3 | 2808 More on Order |

|

BZX84C16W-7-F | DIODE ZENER 16V 200MW SOT323 | 689 More on Order |

|

BZX84C47-TP | 0.35W,47V,ZENER,SOT-23 PKG | 28602 More on Order |

|

BZX84C15-E3-18 | DIODE ZENER 15V 300MW SOT23-3 | 80280 More on Order |

|

BZX84W-B9V1F | BZX84W-B9V1/SOT323/SC-70 | 99858 More on Order |

|

BZX84W-B33F | BZX84W-B33/SOT323/SC-70 | 81750 More on Order |

|

BZX84C5V1LT1G | DIODE ZENER 5.1V 225MW SOT23-3 | 639111 More on Order |