Four challenges of Molex in-car wireless charging

Today's consumers expect their phones to be fully charged at all times - especially in their cars, which are more than just vehicles; For the owner, the car can be used as a kind of movable place to live. However, charging a smartphone in the car is extremely inconvenient. For example, the device does not match, the device is lost, the charging cable is knotted, and connecting the phone while driving will pose a safety hazard. High quality standard in-vehicle wireless charging solutions can provide Oems with flexible design inspiration to design and develop unique and convenient solutions. However, the current situation is that although wireless charging in vehicles is an ideal solution, the development and implementation process is full of challenges.

Challenge one: electromagnetic interference

Technology pioneer Nikola Tesla first demonstrated the potential of wireless charging in 1891 by using wireless "induction" to light an incandescent bulb through energy transmission. Inductive charging converts the input voltage to a constant output voltage in the same way that standard combined circuit components work. The main difference is in the power supply.

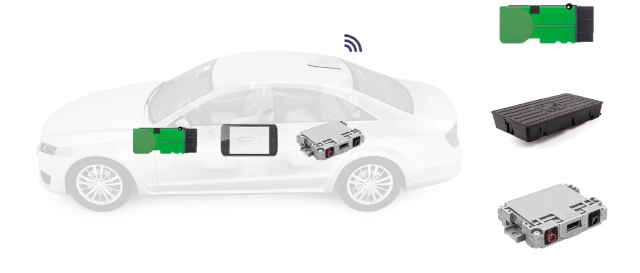

In wireless charging technology, each winding coil used by the power supply part is wound separately. Through the coil in the transmitter module, a magnetic field can be generated at a precise frequency (between 105kHz and 205kHz). The coil in the receiver device receives the same frequency of electrical power and generates a voltage to charge the device's battery.

Electromagnetic compatibility (EMC) standards in automotive applications are very strict. EMC, or unintentionally generated, transmitted and received electromagnetic energy, can adversely affect a vehicle's electrical system, such as electromagnetic interference (EMI). For example, today's car key (KeyFob) system can not only control the door and the trunk of the switch, but also remotely start the car. Wireless charging must not emit electromagnetic waves that will interfere with the keyless start system, otherwise the electromagnetic field generated will have an adverse effect on the car key system.

A more challenging scenario is that once the driver places the car keys on or near the wireless charger, the vehicle's operating system may not find the key signal and the car will not start. Therefore, the development of electromagnetic compatibility shielding technology has a crucial role in the use of car keys and other on-board communication functions to ensure the normal operation of the wireless charging system.

Challenge two: Heat

Extreme temperatures are another challenge. It will have a negative impact not only on mobile devices, but also on wireless charging stations. The general operating temperature of smartphones is 0°C to 35°C. In the hot summer, the temperature inside the car park can reach more than 37°C. In winter, the temperature inside the car can drop below 0°C. If not properly designed and protected, such extreme temperature fluctuations will not only reduce the efficiency of the wireless charging system, but even cause damage and make it unable to work.

Electromagnetic compatibility and temperature fluctuations also affect the efficiency of the system. When transferring power from the platform to the smartphone, some of the energy itself is lost. However, many wireless charging systems are only about 45% efficient under perfect conditions. Electromagnetic shielding and thermal management play an important role in improving the energy efficiency of on-board systems.

Challenge three: Car interiors

The interior of every car is different - it contains unique aesthetics and ergonomics, as well as various electronic functions and interfaces. At the same time, Qi (pronounced "Qi") is the only wireless charging standard currently available, and every phone with built-in wireless charging capabilities will be certified by Qi. Many of these phones have different coil areas, and wireless charging systems must be able to work with each version of the coil, no matter how the phone is positioned at the charging station.

Challenge four: Distance

The charging time of the wireless charging module also depends on the distance between the transmitter and receiver module. Current technology can already reach a distance of 4 millimeters. Longer distances are also possible, but only at higher transmit power levels, which negatively affects the electromagnetic compatibility inside the vehicle. In order to meet the requirements of electromagnetic compatibility standards in the automotive industry, the electric field needs to be reduced below the limit value.

In this regard, the applicable innovative electromagnetic shielding technology, when combined with the protected input circuit, allows the system to exceed the requirements of automotive electromagnetic compatibility. The latest wireless charging modules in the automotive industry are extremely efficient compared to other systems - at a distance of 4 mm between the TX coil (WCh) and the RX coil (smartphone), they achieve 62% efficiency (the ratio of car battery to smartphone battery) at 5 watts of power.

Although in-car wireless charging has gradually begun to be used in connected car solutions, the development and innovation in this area continues. The next generation of devices, which will be available in two to three years, will be able to charge multiple devices simultaneously and be backward compatible. In addition, there are other devices that can also be used by sensing - devices with irregular, non-flat three-dimensional surfaces, such as game consoles, cameras, toys, and wearables can be imagined.

One particularly exciting aspect of the automotive wireless charging market is the integration of near-field communications (NFC), enabling other applications that have traditionally required a high degree of data security. By integrating NFC capabilities, wireless charging technology can also be used for verification, simple pairing, sending points of interest, or as a car key - opening up even more possibilities for future applications in connected cars.

Die Produkte, an denen Sie interessiert sein könnten

|

1824 | SWITCH KEYPAD 12 KEY NON-ILLUM | 7308 More on Order |

|

1189 | SWITCH PUSHBUTTON SPST-NO BLUE | 4446 More on Order |

|

751 | FINGERPRINT SENSOR BIOMETRIC | 4680 More on Order |

|

1293 | SENSOR HUMID/TEMP 5V I2C 2% MOD | 7740 More on Order |

|

3721 | DIGITAL TEMPERATURE AND HUMIDITY | 5958 More on Order |

|

1767 | SLOW VIBRATION SENSOR SWITCH (HA | 16506 More on Order |

|

584 | WIRE STARTER PK EL GRN 2.5M-8.2' | 8496 More on Order |

|

447 | ELECTROLUMINESCN STRIP BLU 100CM | 6588 More on Order |

|

2433 | DOTSTAR LED STRIP - ADDRESSABLE | 6300 More on Order |

|

1734 | ADDRESS LED NEOPIXEL DIFF 8MM TH | 4914 More on Order |

|

2157 | ADDRESS LED 14 SEG I2C WHITE | 6840 More on Order |

|

2851 | ADDRESS LED RING SERIAL RGBW | 7938 More on Order |

|

2562 | ADDRESS LED STRIP SERIAL RGB 1M | 6138 More on Order |

|

2242 | ADDRESS LED STRIP SERIAL RGB 1M | 7650 More on Order |

|

3630 | ADDRESS LED STRIP RGBW | 5850 More on Order |

|

2761 | ADDRESS LED DISCR SER RGBW 1=10 | 7284 More on Order |

|

2757 | ADDRESS LED DISCR SER RGBW 1=10 | 8340 More on Order |

|

1933 | 7"" TFT DISPLAY 800 X 480 | 2394 More on Order |

|

4243 | 2.13"" FLEXIBLE MONOCHROME EINK / | 7866 More on Order |

|

2396 | 7"" TFT DISPLAY 1024 X 600 | 8172 More on Order |

|

159 | DIFFUSED RGB (TRI-COLOR) LED - C | 5994 More on Order |

|

4042 | DIFFUSED RED AND GREEN INDICATOR | 5759 More on Order |

|

1908 | DUAL ALPHANUMERIC DISPLAY - BLUE | 4968 More on Order |

|

811 | YELLOW 7-SEGMENT CLOCK DISPLAY | 8442 More on Order |