Automotive and Industrial innovation: Application prospects for SiC MOSFETs at high temperatures

Today, technology is advancing so fast that electric drive technology has become the core of automotive and industrial equipment design! Everyone is increasingly pursuing energy efficiency and performance, especially in that kind of high temperature operating environment, SiC MOSFET (Silicon carbide metal oxide field effect transistor) ah, with its excellent electrical characteristics, slowly become an indispensable component in power management systems.

Let's talk about the basic principle and characteristics of this SiC MOSFET. This is a semiconductor device made of silicon carbide, which has stronger physical properties than traditional silicon materials. The wide band gap of SIC makes it have higher breakdown voltage, better thermal conductivity and higher operating temperature. Therefore, it is ideal for high temperature, high frequency, high power applications.

First, SiC MOSFETs work well at extreme temperatures. This is very important for cars and industrial equipment, and when you think about it, the temperature often fluctuates up and down when these devices are working, as complex as the environment around the engine compartment or a high-power motor. However, this SiC MOSFETs are impressive, and it can still work stably at temperatures up to 175 degrees Celsius, which is much stronger than traditional silicon-based MOSFETs.

Secondly, silicon carbide materials have high voltage resistance, which allows the design of smaller but more efficient power conversion modules. This reduces the power loss, improves the overall efficiency of the system, and also reduces the heat dissipation requirements, but the design and construction requirements of the system are also high.

Let's talk about its application in electric vehicles. Now the world pays special attention to environmental protection, and the status of electric vehicles in the automotive industry is getting higher and higher. This SiC MOSFET plays a crucial role in the electric drive system of electric vehicles. Its efficient conversion can greatly increase the driving range of electric vehicles, and the charging efficiency can also be significantly improved.

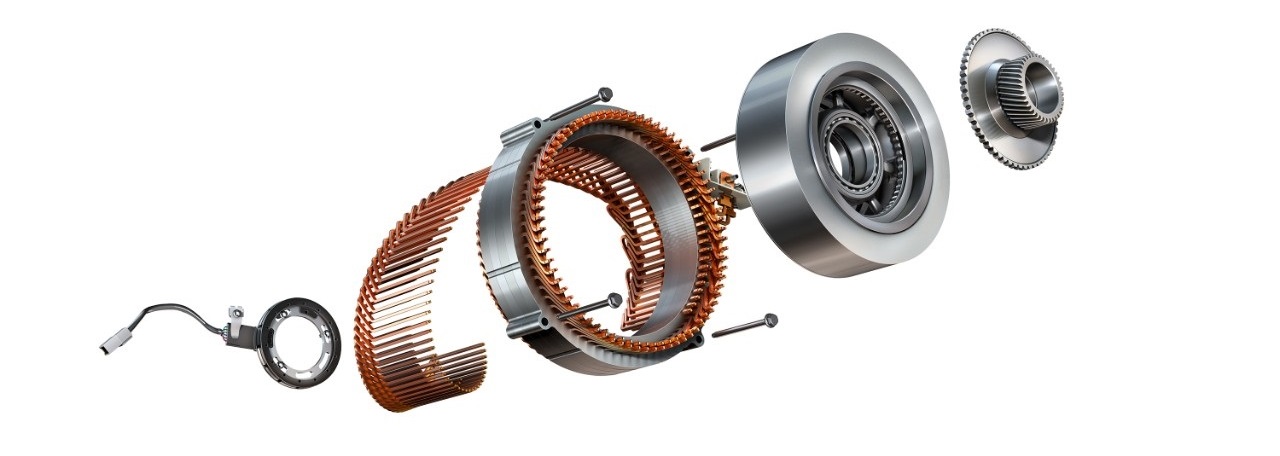

In electric vehicle powertrains, this SiC MOSFET is used in critical components such as inverters and rectifiers. The inverter converts direct current into alternating current to drive an electric motor. This SiC MOSFET switch is fast and can reduce the switching loss of the inverter, thereby improving the efficiency of the entire power system. That means automakers can design lighter, smaller cars without compromising performance. And ah, this thing runs at high temperatures, electric vehicles can work well in extreme environments and can meet the needs of different markets.

In the industrial field, the application prospect of this SiC MOSFET is also quite large. In high-power devices such as welders, frequency converters and motor drivers, SiC MOSFETs provide increased energy efficiency and reliability. Its high switching frequency makes the inverter lighter and smoother.

Think about how harsh the industrial environment is, this SiC MOSFET is high temperature resistant, and the equipment is not easy to fail in high temperature environments. This is of great significance to improve production efficiency and equipment reliability. And this SiC MOSFETs perform well in high-frequency applications and can support more advanced control strategies, such as more complex modulation techniques, which can further improve system performance.

This SiC MOSFET is also an enabler of energy conservation and emission reduction! Governments around the world are strengthening the policy of energy conservation and emission reduction, and the wide application of SiC MOSFET can not only directly improve the energy efficiency of equipment, but also help the entire industrial chain to transform to green. By reducing energy consumption, greenhouse gas emissions can be reduced in many applications, which is in line with the direction of sustainable development.

For example, in the field of renewable energy, such as large-scale wind power, solar and energy storage systems, this SiC MOSFETs are used more often in inverters and power conversion modules. Its high-performance characteristics enable systems in the field to operate stably at higher power levels and optimize resource utilization.

Then there's the manufacturing process. The production process of this SiC MOSFET is different from that of traditional silicon materials, and the manufacturing process and material handling technology are also different. Although the preparation cost of this SiC chip is quite high at the beginning, the price is slowly coming down as the technology advances and the market demand increases, which paves the way for the commercialization of SiC MOSFETs.

At the same time, some semiconductor manufacturers are also continuously improving the design and manufacturing process of this SiC MOSFET to meet the high demand of the market. This includes improving the grid structure, optimizing the body structure design, and improving the consistency and reliability of the product. Manufacturers are still actively exploring the deep application of this material, and hope to further expand it to the military, aerospace and other sectors of the market.

In the trend of increasingly highly integrated and intelligent electric vehicles and industrial equipment, this SiC MOSFET improves energy efficiency and system performance with its superior performance, providing new solutions for a variety of applications. With the continuous progress of market technology, this SiC MOSFET will certainly have broader development prospects in the future automotive and industrial fields

Die Produkte, an denen Sie interessiert sein könnten

|

CAR2548FPBC-Z01A | AC/DC CONVERTER 48V 2500W | 5490 More on Order |

|

SHHN000A3CL4-SRZ | DC DC CONVERTER +/-15V 9W | 6642 More on Order |

|

AXH010A0G5 | DC DC CONVERTER 2.5V 25W | 7866 More on Order |

|

EHHD020A0F64-18HZ | DC DC CONVERTER 3.3V 66W | 3330 More on Order |

|

ATM030A0X3-SRPHZ | DC DC CONVERTER 0.8-2V 60W | 3690 More on Order |

|

QW010A0A1Z | DC DC CONVERTER 5V 50W | 7254 More on Order |

|

JNC350R41Z | DC DC CONVERTER 28V 350W | 5490 More on Order |

|

ATH006A0X4-SRZ | DC DC CONVERTER 0.8-3.6V 21W | 0 More on Order |

|

AXA003A0X4-SRZ | DC DC CONVERTER 0.8-5.5V 16W | 6678 More on Order |

|

LW015F94 | DC DC CONVERTER 3.3V 15W | 8982 More on Order |

|

LW015A84 | DC DC CONVERTER 5V 15W | 7470 More on Order |

|

JW030A1-M | DC DC CONVERTER 5V 30W | 7668 More on Order |

|

JAHW100F1 | DC DC CONVERTER 3.3V 66W | 2808 More on Order |

|

EQW025A0P1-S | DC DC CONVERTER 1.2V 30W | 5742 More on Order |

|

EQW020A0F | DC DC CONVERTER 3.3V 66W | 6300 More on Order |

|

CW025ABK-M | DC DC CONVERTER 5V +/-12V 25W | 2412 More on Order |

|

QBDW033A0B641-HZ | DC DC CONVERTER 12V 400W | 6696 More on Order |

|

JRCW450R641-TZ | DC DC CONVERTER 32V 450W | 6462 More on Order |

|

QBVW033A0B941-HZ | DC DC CONVERTER 12V 400W | 3780 More on Order |

|

PVX012A0X3-SRDZ | DC DC CONVERTER 0.6-5.5V 66W | 8136 More on Order |

|

PNDT006A0X3-SRZ | DC DC CONVERTER 0.45-5.5V | 3294 More on Order |

|

PDT003A0X43-SRZ | DC DC CONVERTER 0.45-5.5V | 4392 More on Order |

|

GDT080A0X43-SRZ | DC DC CONVERTER 0.6-2V | 6720 More on Order |

|

IND066 | DC DC CONVERTER 0.6-5.5V 66W | 8064 More on Order |